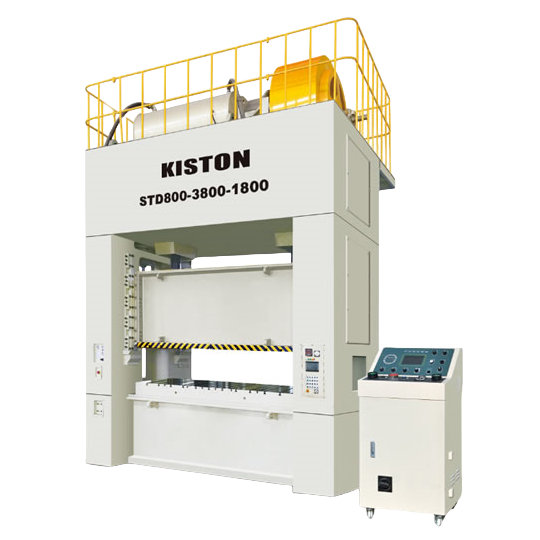

Series:

STS

Series

Phone

Fax

Detailed Introduction

Product Features

Closed box-type welded machine body, good rigidity

Large table and slider area, large distance between columns, easy to operate

High-rigidity cast iron slider, good shock absorption

Eight-sided needle roller guide for slider, high guiding precision

Connecting rod thread hydraulic locking, ensuring accuracy at bottom dead center

Centralized automatic lubrication system, convenient and precise oil supply, ensuring smooth operation of the machine tool

Rotary encoder control, human-machine interface, easy to operate

Specifications

| Type | STS-200 | STS-250 | STS-300 | STS-360 | STS-500 | STS-600 | |||||||

| Tonnage | ton | 200 | 200 | 250 | 250 | 300 | 300 | 360 | 360 | 500 | 500 | 600 | 600 |

| Capacity Point | mm | 4 | 7 | 4 | 7 | 9 | 7 | 8 | 9 | 13 | 7 | 7 | 13 |

| Stroke Length | mm | 40 | 250 | 40 | 250 | 300 | 250 | 250 | 300 | 300 | 300 | 300 | 350 |

| Strokes Per Minute | s.p.m | 60-130 | 20-40 | 50-110 | 20-40 | 20-35 | 20-35 | 20-35 | 15-30 | October 25 | 15-30 | 15-25 | 15-20 |

| Maximum Die Height | mm | 350 | 550 | 380 | 550 | 650 | 550 | 550 | 600 | 700 | 650 | 650 | 700 |

| Maximum Upper Die Weight | Kg | 1000 | 1200 | 800 | 800 | 1500 | 1500 | 1000 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Slide Adjustment | mm | 100 | 150 | 100 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Upper Platen Size | mm | 800x800 | 900x800 | 800x800 | 800x800 | 1000x900 | 1000x900 | 900x900 | 1000x900 | 1200x1200 | 1100x1000 | 1200x1200 | 1200x1200 |

| Lower Platen Size | mm | 900x900 | 1000x900 | 900x900 | 900x900 | 1100x1000 | 1100x1000 | 1000x1000 | 1100x1000 | 1300x1100 | 1200x1100 | 1300x1200 | 1300x1200 |

| Platen Thickness | mm | 170 | 170 | 180 | 180 | 200 | 200 | 200 | 200 | 220 | 220 | 240 | 240 |

| Side Opening | mm | 400x400 | 300x400 | 400x300 | 350x300 | 400x500 | 400x500 | 400x500 | 400x500 | 500x650 | 450x600 | 500x650 | 500x650 |

| Working Height | mm | 850 | 750 | 1060 | 1060 | 750 | 850 | 900 | 950 | 800 | 800 | 700 | 700 |

| Working Energy | KwxP | 800 | 1500 | 1000 | 2000 | 3000 | 2500 | 3000 | 3500 | 7000 | 3800 | 5000 | 8000 |

| Main Motor | HpxP | VS.40x4 | VS.40x4 | VS.40x4 | VS.40x4 | VS.40x4 | VS.40x4 | VS.50x4 | VS.50x4 | VS.60x4 | VS.60x4 | VS.60x4 | VS.60x4 |

| Slide Adjustment Motor | KwxP | 2x4 | 2x4 | 2x4 | 2x4 | 2x4 | 2x4 | 2x4 | 2x4 | 3x4 | 3x4 | 3x4 | 3x4 |

| Frame Structure | One-piece frame | Tie-rod type | |||||||||||

Detailed Configuration

| Standard accessories | Optional accessories |

| Hydraulic overload protection device | Die cushion |

| Motorized slide adjustment device | Slide upper knockout device |

| Digital die height indicator (unit: 0.1MM) | Mold illumination light |

| Slide and die balancing device | Main motor reversal device |

| Rotary cam switch | 3-digit cutting counter |

| Crankshaft angle indicator | Photoelectric safety device |

| Circulating centralized lubrication system | Safety block and safety pin |

| Electromagnetic stroke counter | Preset counter (6 digits) |

| Programmable controller | Load sensing device |

| Air blow connector | Misfeed detection device |

| Air source connector | Inverter |

| Movable T-shaped operation desk | Foundation bolts and foundation plate, anti-vibration device |

| Independent electrical control box | Safety guard and safety ladder |

| Maintenance tools and toolbox | Power plug |

| Quick die change device |

Keywords:

High-precision powerful steel frame punching machine

Adjustable travel heavy-duty steel frame punch press

Double crankshaft precision steel frame press

Semi-closed high-precision powerful steel frame punching machine

Closed-die double-crank precision steel frame punching machine

Single crank precision press

Related Products