Series:

APC

Series

Phone

Fax

Detailed Introduction

Product Features

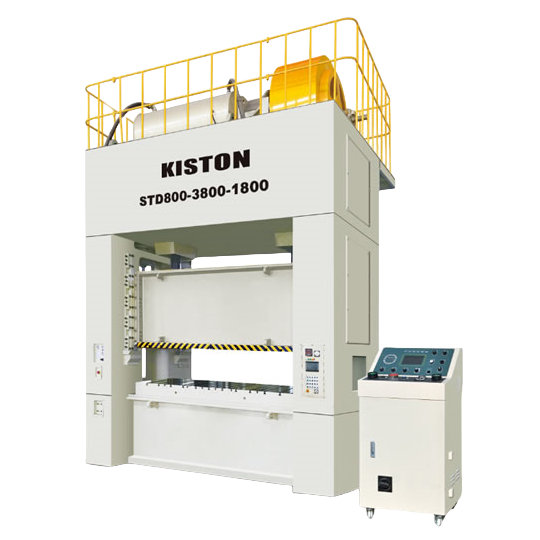

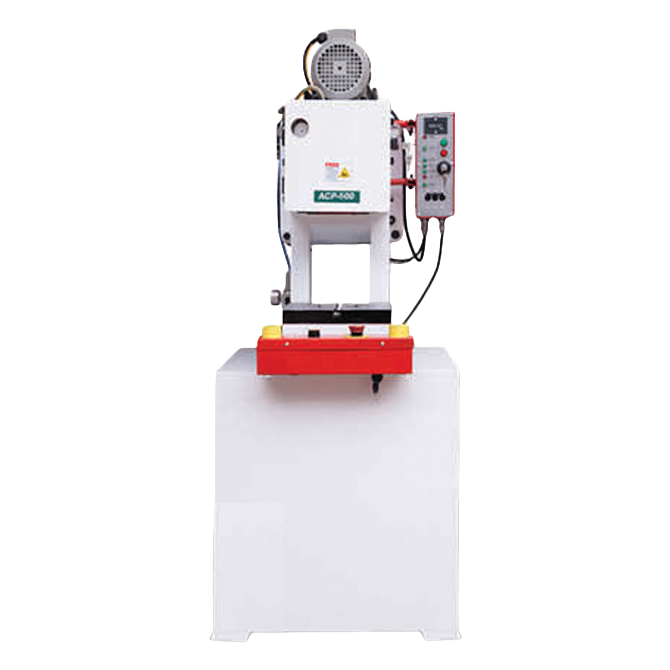

Generally suitable for blanking, punching, bending, and forming operations of medium-sized, continuous die or single-process thin steel plate parts. It can be used for single punching, continuous die, robotic arm connection, or with a conveyor system operation

High-rigidity frame, capable of withstanding larger eccentric loads

Precision transmission mechanism, ensuring long-term accuracy of the press

Multi-functional design, compatible with various automation devices

Complete human-machine protection device, complying with safety press standards

Specifications

| Type | APC-110 | APC-160 | APC-200 | APC-250 | APC-315 | ||||||

| V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | ||

| Tonnage | Ton | 110 | 160 | 200 | 250 | 315 | |||||

| Capacity point | mm | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 8 | 4 |

| Stroke length | mm | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 280 | 170 |

| Strokes per minute | s.q.m | 35-65 | 50-100 | 30-55 | 40-85 | 25-45 | 35-70 | 20-35 | 30-60 | 20-35 | 30-60 |

| Max die height | mm | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 | 550 | 605 |

| Slide adjustment amount | mm | 100 | 100 | 120 | 120 | 120 | |||||

| Upper bolster dimensions | mm | 1400×500×70 | 1600×550×70 | 1850×650×95 | 2100×700×95 | 2100×700×95 | |||||

| Lower bolster dimensions | mm | 1800×650×130 | 2000×760×150 | 2400×840×170 | 2700×900×170 | 2700×900×170 | |||||

| Main motor | KwxP | VS11×4 | VS15×4 | VS18.5×4 | VS22×4 | VS30×4 | |||||

| Press weight | Ton | 14.2 | 20 | 27.5 | 45.5 | 47 | |||||

| Supply air pressure | kg/cm² | 5 | 5 | 5 | 5 | 5 | |||||

| Accuracy | JIS(CIS) Class 1 | ||||||||||

| Die cushion type | Two-plate double cylinder | ||||||||||

| Die cushion capacity | Ton | 3.6×2 | 6.3×2 | 10×2 | 14×2 | 14×2 | |||||

| Die cushion stroke | mm | 70 | 70 | 80 | 100 | 100 | |||||

| Die cushion top plate area | mm | 350×235×2 sets | 410×260×2 sets | 540×350×2 sets | 640×470×2 sets | 640×470×2 sets | |||||

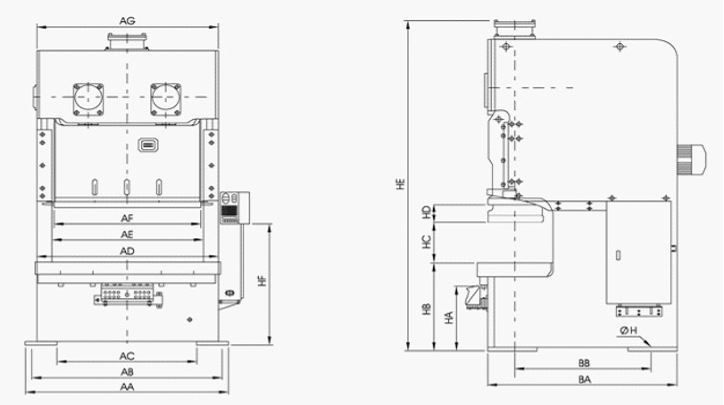

| Specifications | APC-110 | APC-160 | APC-200 | APC-250 | APC-315 | |||||

| Type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type |

| AA | 2000 | 2200 | 2620 | 3000 | 3000 | |||||

| AB | 1900 | 2080 | 2460 | 2800 | 2800 | |||||

| AC | 1360 | 1520 | 1820 | 2200 | 2200 | |||||

| AD | 1800 | 2000 | 2400 | 2700 | 2700 | |||||

| AE | 1510 | 1660 | 1990 | 2220 | 2220 | |||||

| AF | 1400 | 1600 | 1850 | 2100 | 2100 | |||||

| AG | 1780 | 1980 | 2320 | 2590 | 2590 | |||||

| BA | 1745 | 1940 | 2235 | 2545 | 2545 | |||||

| BB | 1295 | 1380 | 1885 | 2195 | 2195 | |||||

| BC | 650 | 760 | 840 | 900 | 900 | |||||

| BD | 330 | 385 | 425 | 455 | 455 | |||||

| BE | 500 | 550 | 650 | 700 | 700 | |||||

| HA | 630 | 730 | 790 | 820 | 820 | |||||

| HB | 830 | 865 | 990 | 1025 | 1070 | 1120 | 1100 | 1155 | 1100 | 1155 |

| HC | 400 | 450 | 500 | 550 | 550 | |||||

| HD | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 280 | 170 |

| HE | 3059 | 3709 | 3849 | 4304 | 4500 | |||||

| HF | 1240 | 1440 | 1570 | 1680 | 1680 | |||||

| ch | 035 | 047 | 054 | 54 | 054 | |||||

Detailed Configuration

| Standard accessories | Optional accessories |

| Inverter | |

| Touch screen | |

| Pre-cut counter | |

| Pre-break counter | |

| Electronic cam | Pneumatic die cushion device |

| Hydraulic overload protection device | Foot switch |

| Motorized slide adjustment device | Quick die change device (die lifter, die clamp or die arm) |

| Motorized grease lubrication device | Upper slide knockout device |

| Slide and die balancing device | Die lighting device |

| Crank angle indicator | Anti-vibration feet |

| Counter | Photoelectric protection device |

| Air source connector | Feeder (air, mechanical, and NC types) |

| Secondary fall protection device | Material rack |

| Mis-feed detection device | Straightener |

| Power socket | Robot arm |

| Maintenance tools and toolbox | |

| Operation manual |

Keywords:

High-precision powerful steel frame punching machine

Adjustable travel heavy-duty steel frame punch press

Double crankshaft precision steel frame press

Semi-closed high-precision powerful steel frame punching machine

Closed-die double-crank precision steel frame punching machine

Single crank precision press

Related Products