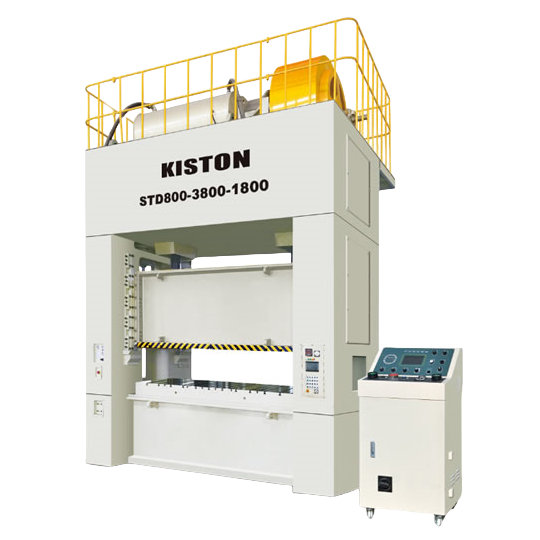

Series:

APF

Series

Phone

Fax

Detailed Introduction

Product Features

· Closed-type, fully welded body eliminates the angle deformation phenomenon of open-type presses.

· Eight-sided slider guidance, long and high-precision guide rails, ensuring smooth and high-precision operation.

· Dry pneumatic friction clutch, low noise, easy maintenance.

· Hydraulic overload protection device, automatic emergency stop in case of overload, protecting the press and die safety, easy to use.

· Automatic lubrication system with oil circuit alarm function, ensuring smooth machine operation.

· Automatic adjustment of die height, digital display, convenient die adjustment.

· Safe PLC centralized electrical control, with emergency stop, inching, single stroke, and continuous operation functions.

· Optional transmission output shaft, automatic feeding, air cushion, and other devices.

Specifications

| Type | APF-110 | APF-160 | APF-200 | APF-260 | APF-300 | APF-400 | APF-500 | APF-600 | ||||||||

| V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | V-type | |||

| Tonnage | ton | 110 | 160 | 200 | 260 | 300 | 400 | 500 | 600 | |||||||

| Capacity occurrence point | mm | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 | 9 | 4.5 | 10 | 13 | |

| Stroke length | mm | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 300 | 170 | 300 | 200 | 250 | 250 | |

| Strokes per minute | Variable speed | s.p.m | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-40 | 35-50 | 15-25 | 20-35 | 20-30 | 15-20 |

| Constant speed | S.P.m | 50 | 35 | 35 | 30 | 30 | 20 | 30 | 20 | |||||||

| Maximum die height | mm | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 615 | 550 | 600 | 500 | 550 | |

| Slide adjustment | mm | 80 | 100 | 110 | 120 | 120 | 150 | 120 | 120 | |||||||

| Upper table size | mm | 1000x550x70 | 1100x600x90 | 1200x650x90 | 1300x700x100 | 1400x800x110 | 1500x850x110 | 1400x800 | 1400x1200 | |||||||

| Lower table size | mm | 1100x600x110 | 1200x800x140 | 1300x820x160 | 1400x840x180 | 1500x950x200 | 1600x1000x200 | 1500x1000 | 1700x1300 | |||||||

| Side opening | mm | 700x500 | 850x600 | 880x650 | 900x700 | 1000x750 | 1000x750 | 900x800 | 1000x900 | |||||||

| Die handle hole | mm | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 | |||||||

| Main motor | kwxp | 11x4 | 15x4 | 18x4 | 22x4 | 30x4 | 40x4 | 55x4 | 75x4 | |||||||

| Slide adjustment motor | HPxP | 0.4x4 | 0.75x4 | 0.75x4 | 1.5x4 | 1.5x4 | 2.2x4 | 3x4 | 3x4 | |||||||

| Air pressure used | kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |||||||

| Press accuracy | GB(JIS) Grade 1 | GB(JIS) Grade 1 | ||||||||||||||

Detailed Configuration

| Standard Accessories | Optional Accessories |

| Inverter | |

| Touch Screen | |

| Pre-cut Counter | |

| Pre-break Counter | Pneumatic Cushion Device |

| Electronic Cam | Foot Switch |

| Hydraulic Overload Protection Device | Quick Mold Change Device (Mold Lifter, Clamping Device or Mold Transfer Arm) |

| Electric Slide Adjustment Device | Upper Ejection Device on Slide |

| Electric Mold Height Indicator | Mold Lighting Device |

| Electric Grease Lubrication Device | Anti-vibration Feet |

| Slide and Mold Balancing Device | Photoelectric Protection Device |

| Crankshaft Angle Indicator | Feeder (Air, Mechanical and NC types) |

| Counter | Material Rack |

| Air Source Connector | Straightening Machine |

| Double-fall Protection Device | Robot Arm |

| Misfeeding Detection Device | |

| Power Socket | |

| Maintenance Tools and Tool Box | |

| Instruction Manual |

Keywords:

High-precision powerful steel frame punching machine

Adjustable travel heavy-duty steel frame punch press

Double crankshaft precision steel frame press

Semi-closed high-precision powerful steel frame punching machine

Closed-die double-crank precision steel frame punching machine

Single crank precision press

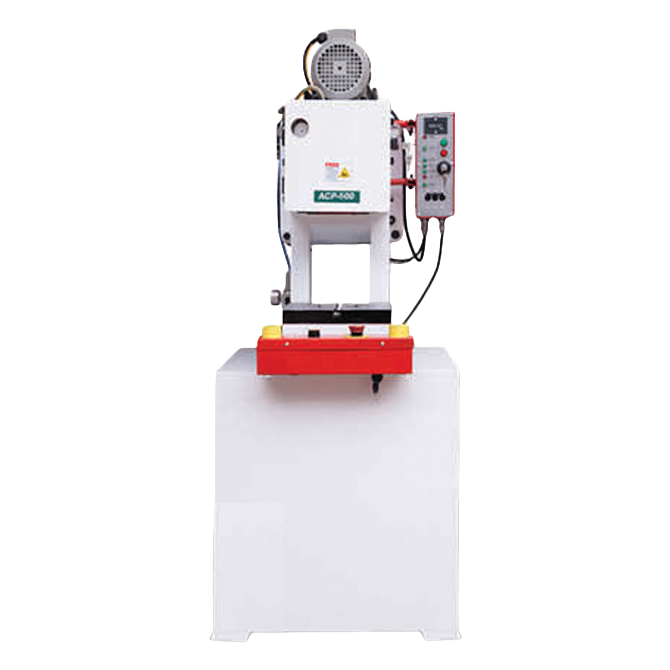

Related Products