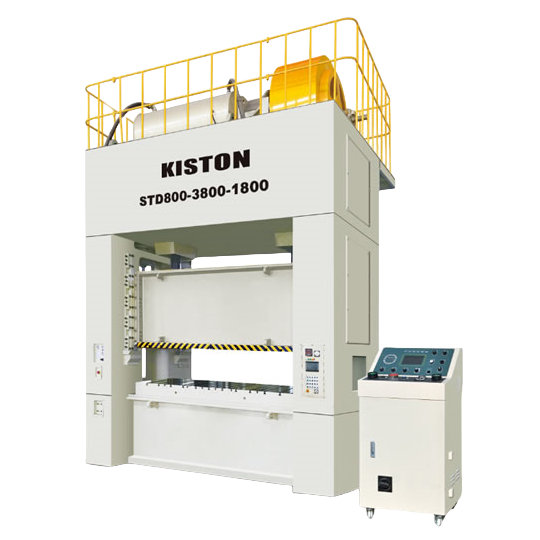

Series:

APH

Series

Phone

Fax

Detailed Introduction

Product Features

Mechanical Structure

· Made of high-strength ductile iron, stress-relieved to reduce operating vibration and noise, extend mold life, and ensure long-term accuracy.

· The mechanism design adopts Engineering Analysis (FEA) computer finite element analysis, ensuring optimal analysis and design for structural strength and overall deformation.

· The connection of the high-rigidity three-section body uses hydraulic fastening, applying hydraulic power to pre-press the frame structure, reducing body deformation and vibration.

Greatly Reduced Vibration and Noise

· Excellent dynamic balance design minimizes vibration and noise during high-speed stamping, and effectively extends mold life.

Precision Spindle - Crankshaft

· The crankshaft is made of chromium-molybdenum alloy copper, heat-treated, and precision-machined using Italian machine tools for grinding.

High Precision, High Stability

· Powerful and sensitive separate clutch and brake ensure positioning accuracy, optimal operational safety, and flexible operation.

Oil Temperature Lubrication Control System

· This machine uses forced circulation oil supply, with an oil temperature regulating device for lubrication and cooling control system, which suppresses thermal deformation, reduces heat strain in the base, improves bottom dead center accuracy, ensures stamping workpiece product precision, extends machine life, and includes a pressure detection function.

Specifications

| Type | APH-125 | APH-200 | APH-300 | |

| Tonnage | ton | 125 | 200 | 300 |

| Stroke | mm | 30 | 30 | 30 |

| Strokes per minute | s.p.m | 150-700 | 150-600 | 150-400 |

| Lower worktable size | mm | 1200x850 | 1700x950 | 2000x1000 |

| Discharge hole | mm | 1000x200 | 1300x250 | 1520x330 |

| Slide area | mm | 1200x600 | 1700x700 | 2000x900 |

| Die height adjustment stroke | mm | 360-410 | 370-420 | 400-450 |

| Die height adjustment motor | KW | 0.75 | 1.5 | 2.2 |

| Feeder height | mm | 195 | 200 | 210 |

| Main motor | kw | 37 | 45 | 50 |

| Press accuracy | Japanese JIS press, top-grade accuracy | |||

Detailed Configuration

| Standard Accessories | Optional Accessories |

| Electric Die Height Adjustment | |

| Die Height Display Accuracy 0.01mm | |

| Jog Positioning Function | |

| Computer can store 10 sets of mold processing data | |

| Three Batch Controls | Bottom Dead Center Accuracy Detector |

| Two Mis-feed Detection | Quick Die Change Device |

| Interlocking unit has 0° and 90° positioning functions | High-speed Feeder |

| Main Machine Forward and Reverse Rotation Device | Double-head Hydraulic Uncoiler |

| Hydraulic Slide Locking Device | Straightener |

| Lubricating Oil Cooling Circulator | Anti-vibration Feet |

| Separate Clutch/Brake | Main Motor Inverter Control |

| Hydraulic Die Lifter | Front and Rear Soundproof Safety Doors |

| Press Controller | |

| Electrical Box | |

| Tool Box | |

| Tool Lamp |

Keywords:

High-precision powerful steel frame punching machine

Adjustable travel heavy-duty steel frame punch press

Double crankshaft precision steel frame press

Semi-closed high-precision powerful steel frame punching machine

Closed-die double-crank precision steel frame punching machine

Single crank precision press

Related Products