Series:

APA

Series

Phone

Fax

Detailed Introduction

1. Safety

Continuously improving the active safety of punch presses is a long-held belief of KISTON. We are always committed to providing users with the safest and most reliable user experience. This concept is fully realized in the APA series.

2. Brakes

All APA series machines are equipped with advanced dry brake clutches. Combined with precise and sensitive dual solenoid valves from TACO Japan, braking time is minimized. Additionally, a secondary braking system provides a second braking signal in emergency situations where the initial braking is insufficient, ensuring timely and accurate braking.

3. User Protection

Maximum user protection was a primary goal during the design phase of the APA series. Therefore, sufficient space is provided between the two-handed operation buttons and the machine body to protect hands. The system is designed to require simultaneous operation of both hands to start, preventing accidental injuries. The addition of photoelectric protection devices or safety nets further enhances user protection.

4. Die Protection

APA series precision punch presses are standard equipped with imported overload devices to protect against die deformation and damage caused by overloading. A mis-feeding detection device is also included, working in conjunction with automatic die-pressing equipment for enhanced die protection.

5. Robustness and Durability

Specifications

| Type | APA-15 | APA-25A | APA-25 | APA-35 | APA-45 | APA-60 | APA-80 | APA-110 | APA-160 | APA-200 | APA-260 | APA-315 | ||||||||||||

| V-type | V-type | V-type | Type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | |||

| Tonnage | Ton | 15 | 25 | 25 | 35 | 45 | 60 | 80 | 110 | 160 | 200 | 260 | 315 | |||||||||||

| Punching force location | mm | 1 | 3.2 | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 8 | 4 | ||

| Strokes per minute | Stroke speed | s.p.m | 120-180 | 60-140 | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 100-150 | 35-90 | 80-120 | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-40 | 40-50 |

| Constant speed | s.p.m | 130 | 110 | 110 | 85 | 75 | 65 | 65 | 50 | 35 | 35 | 30 | 30 | |||||||||||

| Stroke | mm | 60 | 80 | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 | |

| Maximum closing working height | mm | 200 | 195 | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 480 | 510 | 500 | 550 | 500 | 550 | |

| Slider adjustment | mm | 50 | 50 | 50 | 55 | 60 | 75 | 80 | 80 | 100 | 110 | 120 | 120 | |||||||||||

| Upper worktable size | mm | 300x220x50 | 300x220x50 | 300x220x50 | 360x250x50 | 400x300x60 | 50x360x70 | 560x420x70 | 650x470x80 | 700x550x90 | 850x630x90 | 950x700x100 | 950x700x100 | |||||||||||

| Lower worktable size | mm | 680x300x70 | 680x300x70 | 680x300x70 | 800x400x70 | 850x440π80 | 900x500x80 | 1000x550x90 | 1150x600x110 | 1250π800x140 | 1400x820x160 | 1500x840x180 | 1500m840x200 | |||||||||||

| Die holder hole | mm | Ø38.1 | Ø38.1 | Ø38.1 | Ø38.1 | Ø38.1 | Ø50 | Ø50 | Ø50 | Ø65 | Ø65 | Ø65 | Ø65 | |||||||||||

| Main motor | Low.P | 2.2x6 | 4x4 | 4x4 | 4x4 | 5.5x4 | 5.5x4 | 7.5x4 | 11x4 | 15x4 | 18.5x4 | 22x4 | 30x4 | |||||||||||

| Slider adjustment mechanism | HP | Manual | Manual | Electric | ||||||||||||||||||||

| Air pressure used | Kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |||||||||||

| Press accuracy | GB(CIS) Grade 1 | GB(TIS) Grade 1 | GB (JIS) Grade 1 | GB (JIS) Grade 1 | GBCTIS) Grade 1 | GBCTIS) Grade 1 | GB (JIS) Grade 1 | GBCTIS) Grade 1 | GBCIS) Grade 1 | GBCIS) Grade 1 | GB CIS) Grade 1 | GBJIS) Grade 1 | ||||||||||||

| Press (length x width x height) | mm | 1236x856x1920 | 1280x850x2200 | 1280x850x2200 | 1380x900x2400 | 1600x950x2500 | 1600x1000x2800 | 1800x1180x2800 | 1900x1300x3200 | 2300x1400x3800 | 2615x1690x4075 | 2780x1850x4470 | 2780x1850x4500 | |||||||||||

| Press weight | Ton | 1.8 | 2.1 | 2.1 | 3 | 3.8 | 5.6 | 6.5 | 9.6 | 16 | 23 | 32 | 35 | |||||||||||

| Die cushion capacity | Ton | - | - | - | 2.3 | 2.3 | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | 14 | |||||||||||

| Die cushion stroke length | mm | - | - | - | 50 | 50 | 70 | 70 | 80 | 80 | 100 | 100 | 100 | |||||||||||

| Die cushion effective area | mm² | - | - | - | 300x230 | 300x230 | 350x300 | 450x310 | 500x350 | 650x420 | 710x480 | 810x480 | 810x480 | |||||||||||

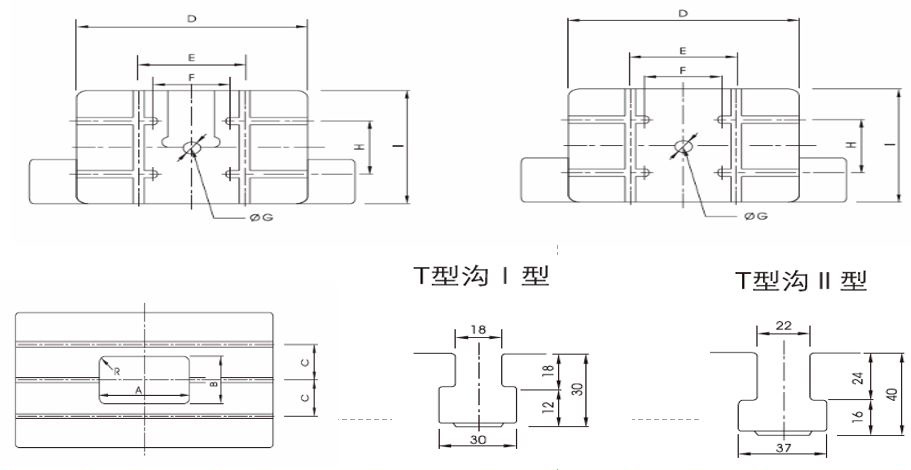

| Model | B | C | D | E | F | G | H | L | T型沟 |

| APA-15 | 100 | 90 | 300 | - | 150 | 838.1 | 80 | 220 | I |

| APA-25A | 120 | 90 | 300 | - | 150 | B38.1 | 80 | 220 | I |

| APA-25 | 120 | 90 | 300 | - | 150 | 838.1 | 80 | 220 | I |

| APA-35 | 140 | 120 | 360 | - | 160 | 838.1 | 100 | 250 | I |

| APA-45 | 150 | 120 | 400 | - | 210 | e38.1 | 120 | 300 | II |

| APA-60 | 160 | 150 | 500 | 220 | 220 | e50 | 160 | 360 | II |

| APA-80 | 180 | 150 | 560 | 300 | 220 | 850 | 180 | 420 | II |

| APA-110 | 200 | 160 | 650 | 300 | 220 | 850 | 220 | 470 | II |

| APA-160 | 220 | 220 | 700 | 300 | 175 | 50 | 220 | 550 | II |

| APA-200 | 240 | 280 | 850 | 420 | 200 | 65 | 300 | 630 | II |

| APA-260 | 260 | 290 | 950 | 420 | 200 | 65 | 300 | 700 | II |

| APA-315 | 260 | 290 | 950 | 420 | 200 | E65 | 300 | 700 | II |

Detailed Configuration

| Standard Accessories | Optional Accessories |

| Inverter | |

| Angle Touch Screen | |

| Pre-cutting Counter | |

| Pre-break Counter | Electric Grease Lubrication Device (Standard for APA160 and above) |

| Electronic Cam | Pneumatic Die Cushion Device |

| Hydraulic Overload Protection Device | Foot Switch |

| Manual Slide Adjustment Device (APA60 and below) | Quick Die Change Device (Die Lifter, Die Clamper, or Die Transfer Arm) |

| Electric Slide Adjustment Device (APA60 and above) | Upper Die Feeding Device |

| Mechanical Die Height Indicator (APA60 and below) | Die Lighting Device |

| Electric Die Height Indicator (APA60 and above) | Anti-vibration Feet |

| Slide and Die Balancing Device | Photoelectric Protection Device |

| Crankshaft Angle Indicator | Feeder (Air, Mechanical, and NC types) |

| Counter | Material Rack |

| Air Source Connector | Straightening Machine |

| Double-fall Protection Device | Robot Arm |

| Misfeeding Detection Device | |

| Power Socket | |

| Maintenance Tools and Tool Box | |

| Instruction Manual |

Keywords:

High-precision powerful steel frame punching machine

Adjustable travel heavy-duty steel frame punch press

Double crankshaft precision steel frame press

Semi-closed high-precision powerful steel frame punching machine

Closed-die double-crank precision steel frame punching machine

Single crank precision press

Related Products