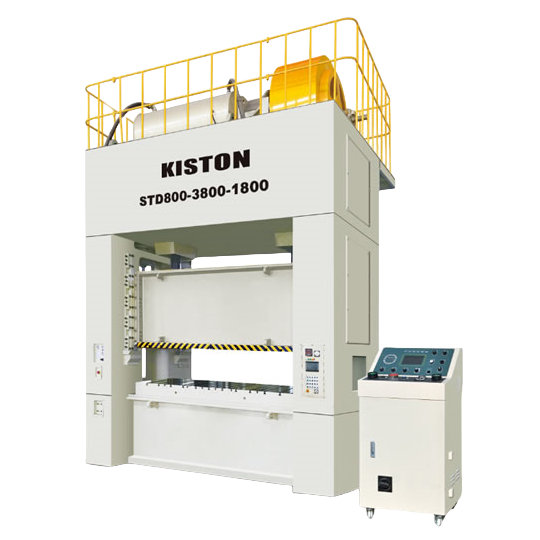

Series:

APD

Series

Phone

Fax

Detailed Introduction

Product Features

Widely used in stamping and forming of electronics, communication, computers, home appliances, furniture, power tools (automobiles, motorcycles, bicycles), hardware parts, etc.

Integrated straight-sided frame, suitable for precision progressive die processing.

Eliminates the open throat disadvantage of C-frame presses, saving mold maintenance costs.

High-rigidity frame, guide rails on the punch center line and long support stroke, ensuring long-term dynamic stability and extended mold life.

The punch bottom area is 15~25% larger than C-frame presses, allowing for an increase in mold engineering and higher value-added processing.

High-torque wet brake clutch with long lining life and low maintenance costs; pollution-free, low noise, meets environmental requirements. High safety, high affinity, multi-functional electronic control system.

Can be matched with various automation equipment, easy to operate.

Electric punch adjustment device: This adjustment device uses a thin brake motor and is operated by buttons. Its advantages are precise positioning, stable mechanism, and rapid lifting and lowering adjustment.

Simple punch adjustment device: Simple and reliable manual die height adjustment equipment with a 0.1mm indicator.

Electric grease pump: Automatic timed centralized lubrication pump and fault detection system, ensuring stable operation.

Specifications

| Type | APD-80 | APD-110 | APD-160 | APD-200 | APD-260 | APD-315 | |||||||

| V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | ||

| Tonnage | Ton | 80 | 110 | 160 | 200 | 260 | 315 | ||||||

| Punching force location | mm | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Stroke | mm | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 280 | 170 |

| Maximum closing working height | mm | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 600 |

| Strokes per minute | S.p.m | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 20-50 | 20-35 | 30-50 |

| Slide adjustment | mm | 80 | 80 | 100 | 110 | 120 | 120 | ||||||

| Upper table size | mm | 560x420x70 | 650x470x80 | 700x550x90 | 850x630x90 | 950x700x100 | 1000x750x110 | ||||||

| Lower table size | mm | 760x550x90 | 1090x600x110 | 1190x880x140 | 1400x820x160 | 1530x840x180 | 1600x900x200 | ||||||

| Main motor | kw.p | 7.5x4 | 11x4 | 15x4 | 18.5x4 | 22x4 | 30x4 | ||||||

| Slide adjusting mechanism | HP | Electric | |||||||||||

| Air pressure used | kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| Press (length x width x height) | mm | 1300x1890x3000 | 1420x1985x3200 | 1600x2200x3500 | 1750x2500x3900 | 2780x1850x4470 | 2100x2925x4550 | ||||||

| Press weight | Ton | 7.8 | 10.5 | 17.8 | 25.3 | 37 | 42 | ||||||

| Press accuracy | GB(JIS) Grade 1 | ||||||||||||

| Die cushion capacity | Ton | 3.6 | 6.3 | 10 | 14 | 14 | 14 | ||||||

| Die cushion stroke length | mm | 70 | 80 | 80 | 100 | 100 | 100 | ||||||

| Die cushion effective area | mm² | 450x310 | 500x350 | 650x420 | 710x480 | 810x480 | 810x480 | ||||||

Detailed Configuration

| Standard Accessories | Optional Accessories |

| Inverter | |

| Touch Screen | |

| Pre-cut Counter | |

| Pre-break Counter | Pneumatic Cushion Device |

| Electronic Cam | Foot Switch |

| Hydraulic Overload Protection Device | Quick Mold Change Device (Mold Lifter, Clamping Device or Mold Transfer Arm) |

| Electric Slide Adjustment Device | Upper Ejection Device on Slide |

| Electric Mold Height Indicator | Mold Lighting Device |

| Electric Grease Lubrication Device | Anti-vibration Feet |

| Slide and Mold Balancing Device | Photoelectric Protection Device |

| Crankshaft Angle Indicator | Feeder (Air, Mechanical and NC types) |

| Counter | Material Rack |

| Air Source Connector | Straightening Machine |

| Double-fall Protection Device | Robot Arm |

| Misfeeding Detection Device | |

| Power Socket | |

| Maintenance Tools and Tool Box | |

| Instruction Manual |

Keywords:

High-precision powerful steel frame punching machine

Adjustable travel heavy-duty steel frame punch press

Double crankshaft precision steel frame press

Semi-closed high-precision powerful steel frame punching machine

Closed-die double-crank precision steel frame punching machine

Single crank precision press

Related Products