Service Support

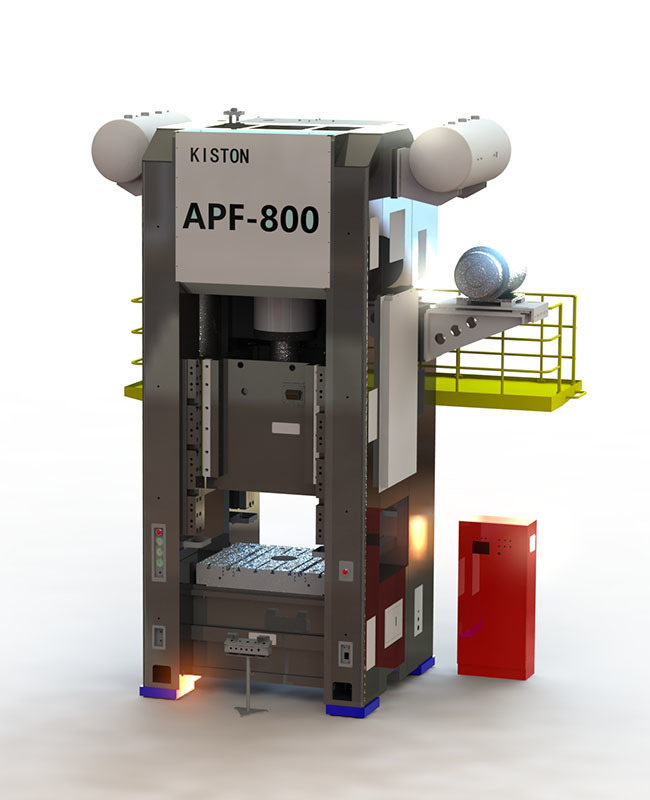

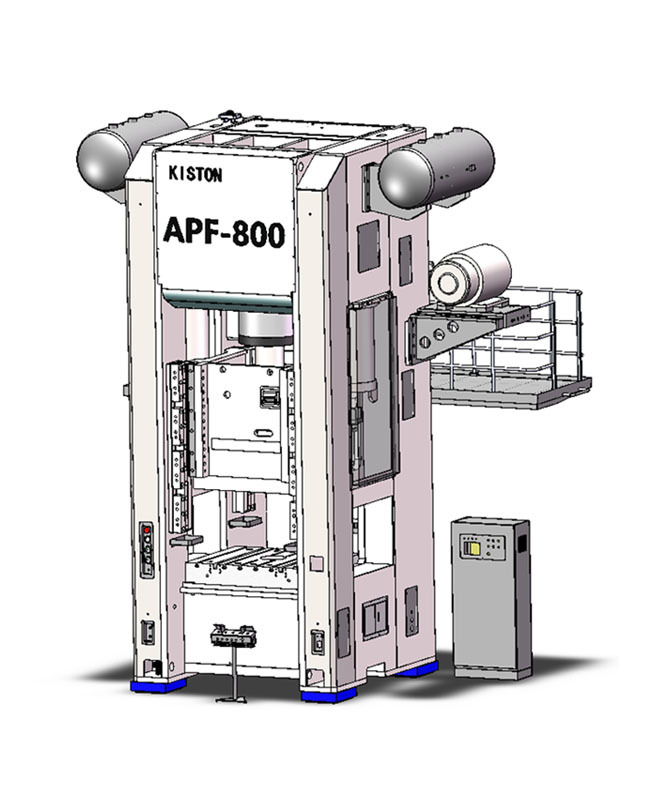

Advanced SOLIDWORKS 3D solid modeling design

The product adopts advanced SOLIDWORKS three-dimensional solid modeling design technology;

3D design has the following significant advantages:

① Strong intuitiveness, easy to find spatial interference problems in the design, greatly reducing the error rate in the design process;

② Improve work efficiency, conveniently and quickly import 3D into 2D, greatly improving the efficiency of engineers' drawing output;

③ The borrowing of common parts between models can greatly reduce the amount of repetitive work.

FAQ

How to better solve the noise problem of the punching machine?

1. Eliminate operational machinery noise

Mechanical presses often use crank-slider transmission mechanisms. To reduce gaps, bearings should be installed according to specified requirements; bearings can use higher viscosity lubricants to increase resistance and reduce the equipment's no-load noise. Place anti-vibration pads such as thin metal plates, rubber, or plastic at the collision points between the damping layer and metal components to reduce noise generated by impact.

2. Improve machine tool structure

The open-front double-column fixed-table press series and open-front double-column inclinable press series have been changed to friction clutches. The punch press transmission system can be changed to helical gears or herringbone gears. This basically eliminates this impact noise. To blow off stamped parts, try to use less or no high-pressure compressed air, and slightly tilt the machine body.

3. Set up sound absorption and vibration reduction equipment

The punch press flywheel, its transmission system, and the machine cover are all enclosed, which can significantly reduce noise in the transmission area. High-power, high-noise motors should be equipped with partial sound insulation covers or enclosed sound insulation covers. This allows for more effective handling of noise issues. A movable protective grille or sound insulation cover is installed at the bottom of the slider or outside the mold operating area. If a sound insulation cover is applied to the outside of the mold, and sound-absorbing material is attached to the inner wall of the cover, the noise reduction effect will be greater.

Soundproof cotton or earplugs can also be used to reduce the impact of pressing noise on individuals, but the fundamental solution should still start from the noise source. This can be improved by refining equipment structure, or hopefully, it can help us by using some effective equipment.